|

Message Board >

"Avoid Common Mistakes in Heavy Steel Fabrication:

"Avoid Common Mistakes in Heavy Steel Fabrication:

Page:

1

Guest

Guest

Dec 16, 2025

10:57 PM

|

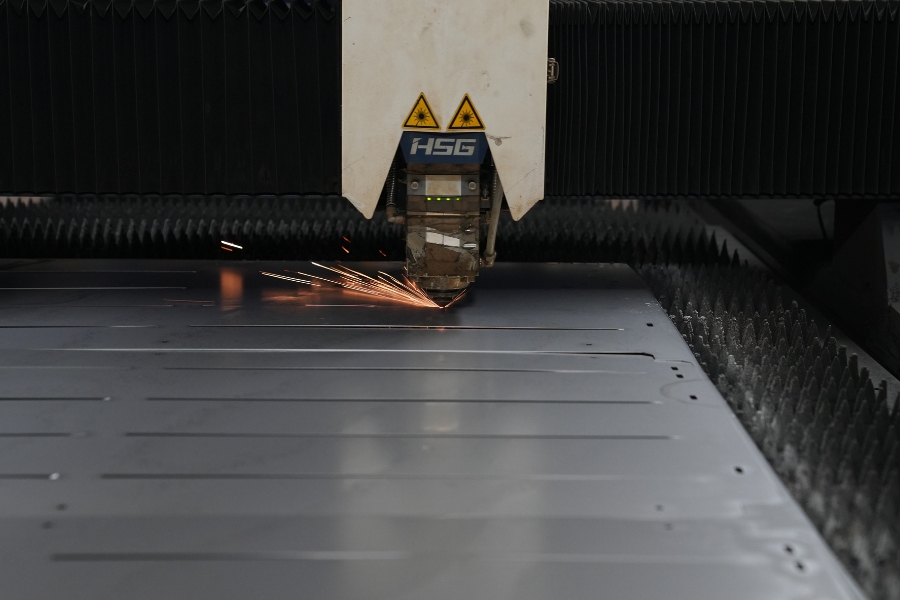

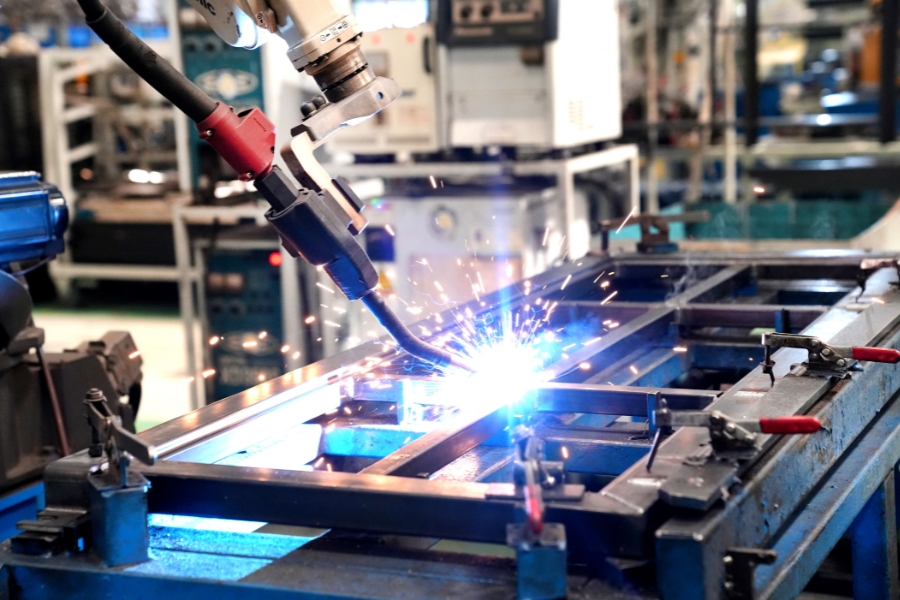

Heavy steel fabrication is an essential process in mechanical engineering and supporting industries, yet it is fraught with common mistakes that can lead to costly delays and safety hazards. Understanding these pitfalls and implementing preventive measures is crucial for successful project execution. In this article, we will explore the most frequent mistakes encountered in heavy steel fabrication and provide practical strategies to avoid them, ensuring a smoother workflow and enhanced productivity.

See Article Details At: heavy steel fabrication

Neglecting Proper Planning

One of the most significant mistakes in heavy steel fabrication is failing to plan adequately. Without a comprehensive plan, projects can quickly spiral out of control, resulting in wasted resources and time. To avoid this:

View At: Why Heavy Steel Fabrication Matters

- Define Clear Objectives: Establish specific goals for your project, including timelines, budgets, and quality standards.

- Conduct Feasibility Studies: Assess the project's feasibility by analyzing materials, labor, and equipment requirements.

- Develop Detailed Project Plans: Create a step-by-step plan that outlines every aspect of the project, from design to execution.

Ignoring Quality Control

Quality control is critical in heavy steel fabrication; however, many companies overlook it, leading to defective products and increased costs. To mitigate this risk:

- Implement Inspection Protocols: Establish regular inspections at various stages of fabrication to catch defects early.

- Train Your Team: Ensure that all workers are trained in quality standards and understand the importance of their role in maintaining quality.

- Use Advanced Technologies: Invest in technology that enhances quality control, such as automated inspection systems.

Underestimating Safety Measures

Safety should always be a top priority in heavy steel fabrication, yet many overlook essential safety measures. This negligence can lead to accidents and injuries. To enhance safety:

- Conduct Regular Safety Training: Provide ongoing training sessions that cover safety protocols and emergency procedures.

- Utilize Personal Protective Equipment (PPE): Ensure that all workers wear appropriate PPE, such as helmets, gloves, and safety glasses.

- Maintain Equipment: Regularly inspect and maintain all machinery and tools to prevent malfunctions that could cause accidents.

Failing to Communicate Effectively

Poor communication is a common pitfall in heavy steel fabrication, leading to misunderstandings and errors. To foster effective communication:

- Establish Clear Channels: Create designated communication channels for team members to share updates and concerns.

- Encourage Open Dialogue: Foster a workplace culture where employees feel comfortable discussing challenges and suggestions.

- Use Collaboration Tools: Implement project management software to track progress and facilitate communication among team members.

Neglecting Post-Fabrication Processes

After the fabrication process, many companies fail to prioritize post-fabrication tasks, such as finishing, assembly, and transport. This oversight can result in delays and increased costs. To address this:

- Plan for Post-Fabrication: Include post-fabrication processes in the initial project plan and allocate resources accordingly.

- Conduct Thorough Testing: Perform tests and inspections after fabrication to ensure the final product meets specifications.

- Prepare for Transportation: Develop a logistics plan for transporting finished products safely and efficiently.

Conclusion

In summary, heavy steel fabrication plays a vital role in mechanical engineering and related industries, but it is not without its challenges. By recognizing common mistakes such as neglecting planning, quality control, safety measures, effective communication, and post-fabrication processes, companies can take proactive steps to avoid these pitfalls. By following the strategies outlined in this article, you can enhance your fabrication processes, reduce costs, and improve overall project outcomes. Don't wait for mistakes to happen—start implementing these best practices today for more efficient and safer heavy steel fabrication. THACO Industries is a leading industrial manufacturing partner in Vietnam, providing comprehensive OEM solutions for global businesses. Partner with THACO Industries for a comprehensive OEM manufacturing service in Vietnam, covering end-to-end design, fabrication, assembly, testing, and logistics to ensure consistent quality and efficiency.

#heavy_steel_fabrication, #heavysteelfabrication, #THACO_Industries, #THACOIndustries, #THACO_Industries

|

Post a Message

Real Estate Provider #515.000066/Fahim Muhammad Instructor #512.003026/Fahim Muhammad Managing Broker #471.020985 Freedom Financial Institute, IDOI Provider #500026517/NMLS Provider #1405073/Fahim Muhammad NMLS #1851084 All loans originated through Mortgage Loan Direct, NMLS #1192858 15255 South 94th Avenue, Suite 500 Orland Park, IL 60462. Freedom Apex Enterprise & Financial Services Mailing Address: 837 East 162nd Street, Suite 7-8 South Holland, IL 60473 708-704-7309/708-566-1222, 844-49-FREEDOM

FINRA Broker Check

Disclaimer and Release Nothing contained on this website constitutes tax, legal, insurance or investment advice, or the recommendation of or an offer to sell, or the solicitation of an offer to buy or invest in any investment product, vehicle, service or instrument.The information shared is hypothetical and for informational and educational purposes only. Such an offer or solicitation may only be made and discussed by a registered representative of a broker dealer or investment advisor representative of an investment advising firm. You should note that the information and materials are provided "as is" without any express or implied warranties. Past performance is not a guarantee of future results. All investments involve a degree of risk, including a degree of loss. No part of FTAMG’s materials may be reproduced in any form, or referred to in any other publication, without express written permission from FTAMG and or its affiliates. Links to appearances and articles by Fahim Muhammad, The Freedom Coach, whether in the press, on television or otherwise, are provided for informational and educational purposes only and in no way should be considered a recommendation of any particular investment product, vehicle, service or instrument or the rendering of investment advice, which must always be evaluated by a prospective investor in consultation with his or her own financial adviser and in light of his or her own circumstances, including the investor's investment horizon, appetite for risk, and ability to withstand a potential loss of some or all of an investment's value. By using this website, you acknowledge that you have read and understand the foregoing disclaimers and release FTAMG and its affiliates, members, officers, employees and agents from any and all liability whatsoever relating to your use of this site, any such links, or any information contained herein or in any such appearances or articles (whether accessed through such links or downloaded directly from this website). FTAMG highly encourages its viewers and potential clients to obtain the independent advice and services of legal, financial, and tax professionals.

Securities offered through The Leaders Group, Inc. member FINRA/SIPC 475 Springfield Avenue, Suite 1 Summit, NJ 07901 (303) 797-9080

info@freedomfinancialinstitute.orgCopyright© 2025 - Fahim Muhammad Freedom Financial Institute, Inc.

|

|

|