|

Message Board >

"Step-by-Step Guide to Kitting and Assembly Servic

"Step-by-Step Guide to Kitting and Assembly Servic

Page:

1

Guest

Guest

Dec 17, 2025

9:30 AM

|

In the world of mechanical engineering and supporting industries, kitting and assembly services play a pivotal role in enhancing efficiency and reducing production costs. This step-by-step guide will walk you through the essential phases of implementing these services effectively. Whether you're a novice in the field or looking to refine your existing processes, understanding the intricacies of kitting and assembly can significantly impact your operational success.

See Article Details At: kitting and assembly services

Step 1: Understanding Kitting and Assembly Services

Kitting is the process of gathering all the necessary components and materials required for production into a single kit, while assembly involves putting those components together to create the final product. Recognizing the importance of both kitting and assembly is crucial to streamlining your manufacturing operations. This phase sets the stage for increased productivity and reduced lead times.

See More At: Why Kitting and Assembly Services Matter

Step 2: Conducting a Needs Assessment

Before diving into kitting and assembly, conduct a comprehensive needs assessment. This step involves:

- Identifying Key Products: Determine which products will benefit most from a kitting and assembly approach. Look for items with complex assembly requirements or those that are frequently ordered together.

- Analyzing Current Processes: Review existing workflows to identify bottlenecks and areas for improvement. Understanding where inefficiencies lie will help you tailor your kitting solutions effectively.

- Gathering Input from Stakeholders: Engage with teams from production, supply chain, and quality control to gather insights. This collaboration ensures that the kitting process aligns with broader organizational goals.

Step 3: Designing the Kitting Process

Once the needs assessment is complete, you can begin designing your kitting process. Key considerations include:

- Kit Configuration: Decide on the structure of your kits. Will they include all components for a single product, or multiple items for various products? Ensure that the configuration meets the assembly requirements.

- Inventory Management: Implement an effective inventory management system to track components. This ensures that you have the right materials on hand at all times, reducing delays in production.

- Packaging Solutions: Choose appropriate packaging for the kits to protect components and facilitate easy transportation. The packaging should be designed for efficiency in handling and storage.

Step 4: Implementing Assembly Procedures

With your kitting process in place, focus on establishing assembly procedures. This step is crucial for maintaining quality and efficiency:

- Workstation Setup: Design assembly workstations that promote efficiency and ergonomics. Ensure that tools and components are easily accessible to assembly workers.

- Standard Operating Procedures (SOPs): Develop clear SOPs for each assembly task. These documents should outline step-by-step instructions, safety protocols, and quality checks to follow during assembly.

- Training and Development: Equip your workforce with the necessary skills through training programs. Well-trained employees are more productive and contribute to higher quality outputs.

Step 5: Quality Control Measures

Quality control is paramount in both kitting and assembly services. Implement the following measures to ensure high standards:

- Inspection Processes: Introduce inspection checkpoints throughout the kitting and assembly stages. This allows for early detection of defects and reduces the risk of faulty products reaching customers.

- Feedback Mechanisms: Foster a culture of continuous improvement by encouraging feedback from assembly workers and quality control teams. Use this feedback to refine processes and address issues promptly.

- Audit and Review: Regularly audit kitting and assembly processes to identify areas for enhancement. This can involve reviewing performance metrics, customer complaints, and production downtime incidents.

Conclusion: Streamlining Your Operations with Kitting and Assembly Services

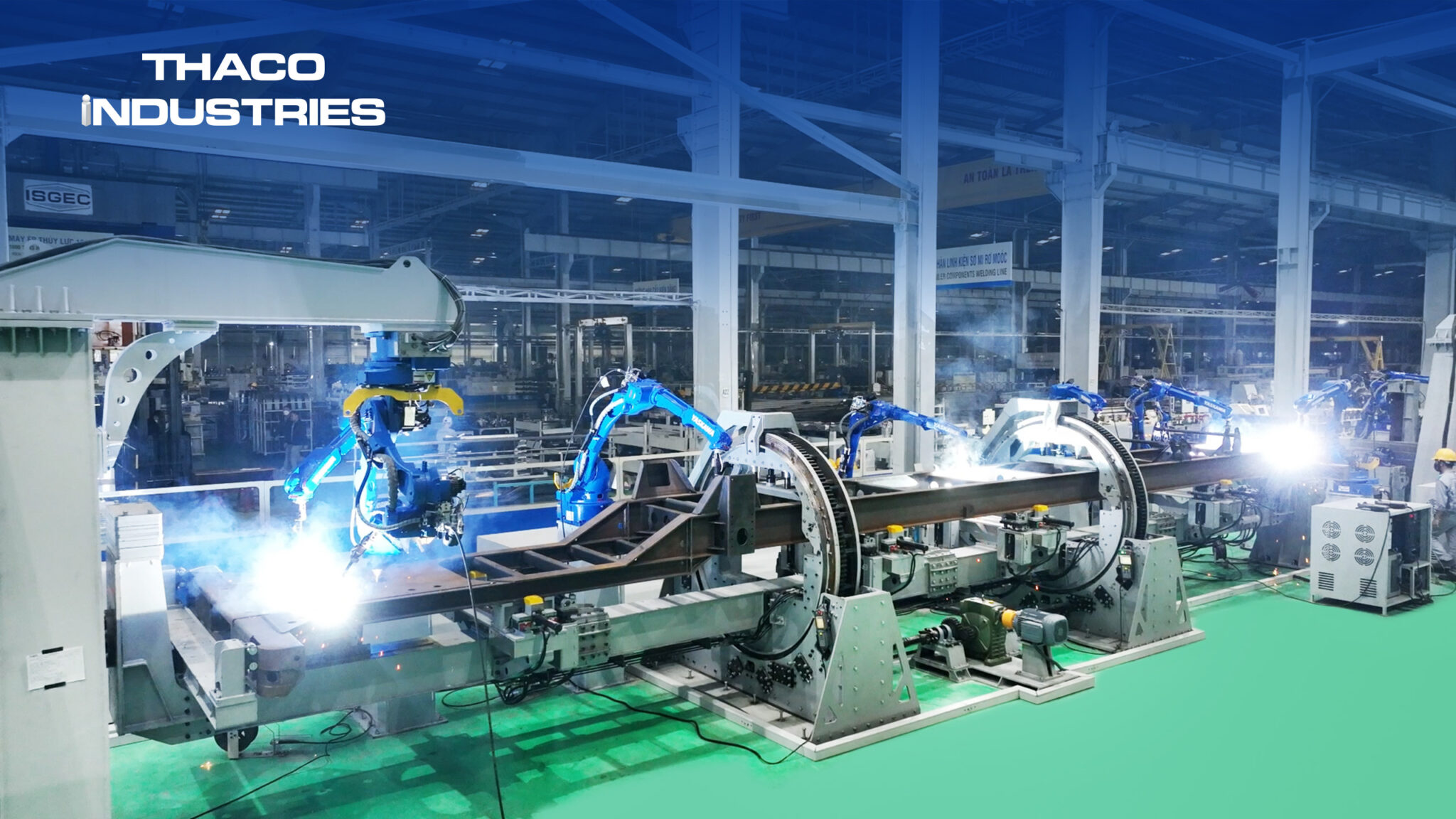

In conclusion, kitting and assembly services are integral to optimizing operations within the mechanical engineering and supporting industries. By following this step-by-step guide, you can implement effective kitting and assembly practices that enhance productivity, reduce costs, and improve product quality. Start your journey today by assessing your needs and designing a tailored kitting and assembly process that drives efficiency in your organization. THACO Industries is a leading industrial manufacturing partner in Vietnam, providing comprehensive OEM solutions for global businesses. Partner with THACO Industries for a comprehensive OEM manufacturing service in Vietnam, covering end-to-end design, fabrication, assembly, testing, and logistics to ensure consistent quality and efficiency.

#kitting_and_assembly_services, #kittingandassemblyservices, #THACO_Industries, #THACOIndustries, #THACO_Industries

|

Post a Message

Real Estate Provider #515.000066/Fahim Muhammad Instructor #512.003026/Fahim Muhammad Managing Broker #471.020985 Freedom Financial Institute, IDOI Provider #500026517/NMLS Provider #1405073/Fahim Muhammad NMLS #1851084 All loans originated through Mortgage Loan Direct, NMLS #1192858 15255 South 94th Avenue, Suite 500 Orland Park, IL 60462. Freedom Apex Enterprise & Financial Services Mailing Address: 837 East 162nd Street, Suite 7-8 South Holland, IL 60473 708-704-7309/708-566-1222, 844-49-FREEDOM

FINRA Broker Check

Disclaimer and Release Nothing contained on this website constitutes tax, legal, insurance or investment advice, or the recommendation of or an offer to sell, or the solicitation of an offer to buy or invest in any investment product, vehicle, service or instrument.The information shared is hypothetical and for informational and educational purposes only. Such an offer or solicitation may only be made and discussed by a registered representative of a broker dealer or investment advisor representative of an investment advising firm. You should note that the information and materials are provided "as is" without any express or implied warranties. Past performance is not a guarantee of future results. All investments involve a degree of risk, including a degree of loss. No part of FTAMG’s materials may be reproduced in any form, or referred to in any other publication, without express written permission from FTAMG and or its affiliates. Links to appearances and articles by Fahim Muhammad, The Freedom Coach, whether in the press, on television or otherwise, are provided for informational and educational purposes only and in no way should be considered a recommendation of any particular investment product, vehicle, service or instrument or the rendering of investment advice, which must always be evaluated by a prospective investor in consultation with his or her own financial adviser and in light of his or her own circumstances, including the investor's investment horizon, appetite for risk, and ability to withstand a potential loss of some or all of an investment's value. By using this website, you acknowledge that you have read and understand the foregoing disclaimers and release FTAMG and its affiliates, members, officers, employees and agents from any and all liability whatsoever relating to your use of this site, any such links, or any information contained herein or in any such appearances or articles (whether accessed through such links or downloaded directly from this website). FTAMG highly encourages its viewers and potential clients to obtain the independent advice and services of legal, financial, and tax professionals.

Securities offered through The Leaders Group, Inc. member FINRA/SIPC 475 Springfield Avenue, Suite 1 Summit, NJ 07901 (303) 797-9080

info@freedomfinancialinstitute.orgCopyright© 2025 - Fahim Muhammad Freedom Financial Institute, Inc.

|

|

|